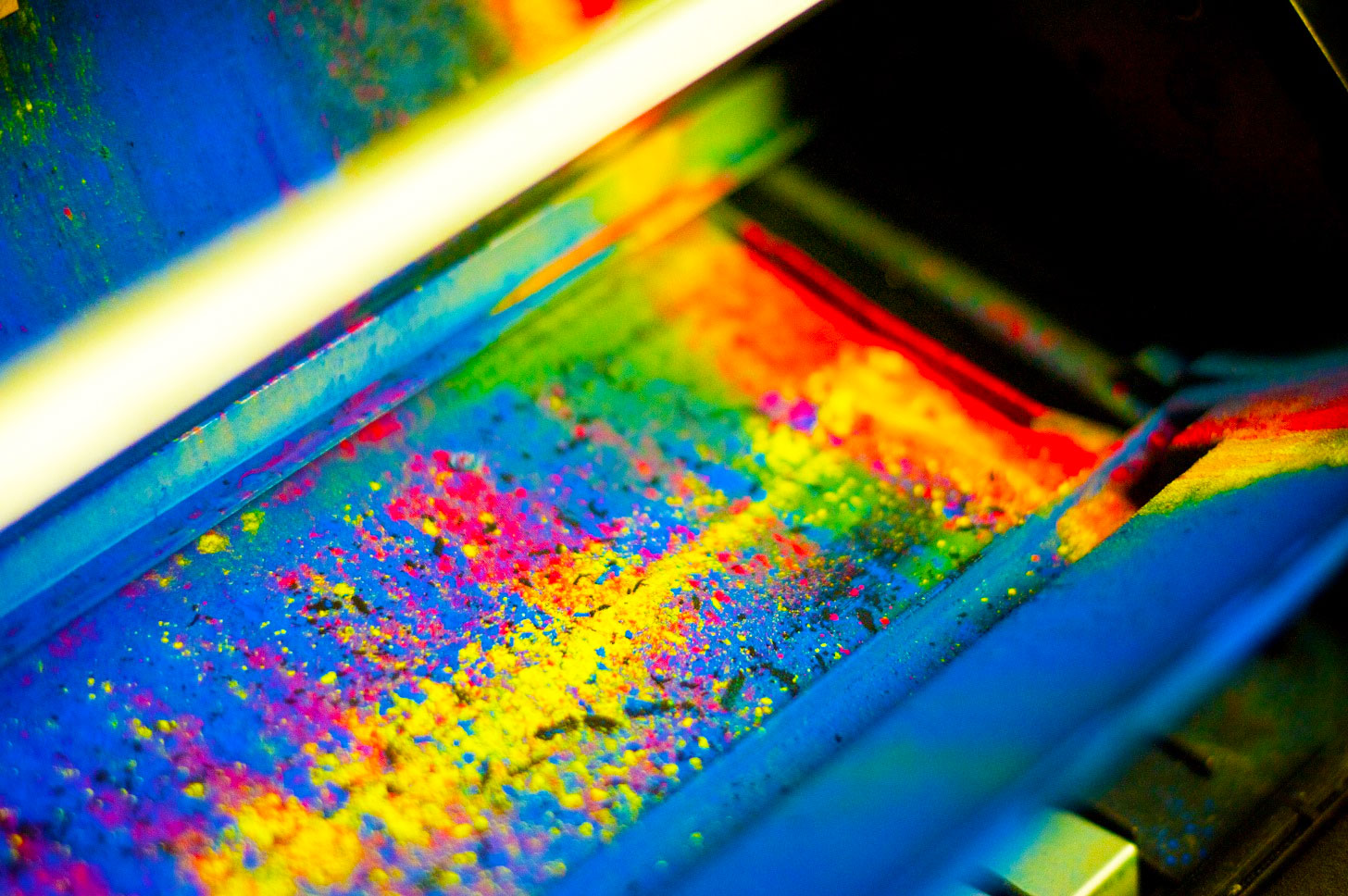

Four-Color printing can add an exciting dimension to your marketing materials that can be much more dramatic than simple one or two-color printing. One or two-color printing is not necessarily inferior to four-color, but the question should be: is four-color printing really necessary for the project on hand?

For example, a direct mail piece or marketing brochure that is introducing your company for the first time to a potential customer should make a great first impression and four-color printing may be the best way to communicate your products or services. However, an assembly instruction booklet to be included with a product may work fine as a one- or two-color printing project.

Four-Color Pros:

Many clients and designers often feel that four-color process printing gives them the most design flexibility. With four-color process printing, any color imaginable can be created, allowing the designer to make text in color or to use graphic elements for emphasis that literally jump off the page.

Photographs can be reproduced in color, making product images much more believable and many different colored screen tints are possible giving a designer an almost limitless palette to work with when designing.

If you are trying to produce a show-and-tell brochure where photographs are vital to explain a service, process, or product, then four-color process printing is your logical choice, regardless of the price.

Four-Color Cons:

While printing costs have become much more competitive over the years as more printers have gone to digital printing (with digital files outputting directly to plates), the pre-press work is still quite involved, though much of it is now done by graphic designers, instead of by printers.

If you have photographs or transparencies, they will need to be scanned, though digital photography does eliminate the need for scanning. Color images will still need to be color corrected and in some cases, some work will need to be done in PhotoShop to improve a photograph’s contrast and clarity.

Other pre-press work may include converting photograph files from RGB to CMYK and making sure all images are sized properly and have adequate resolution for printing.

Simple one or two-color printing jobs have less pre-press work and fewer plates to be made and tend to be less expensive to print than four-color.

Trying to reproduce some PMS (Pantone Matching System) colors using a four-color process can be difficult if not impossible with some colors. Often a client will have a logo or design element that has been printed on past materials as a PMS spot color and is upset when the same color cannot be created accurately using a four-color process.

Most four-color printing requires coated paper stock in order to produce the best color fidelity. While you can print four-color process on uncoated and textured stock, many clients find the softness and lack of contrast of the printed reproductions to be less than desirable when uncoated stock is used.

Often it is necessary to varnish or apply liquid lamination to large four-color areas or large solid areas in order to limit fingerprinting, especially on brochure and pocket folder covers. This is sometimes viewed as an option but is really necessary to make sure a quality piece makes a great first impression.

Four-color printing also requires proofing of all color proofs prior to printing to ensure true color fidelity, and it is a common practice for the client and designer to be present during press runs to approve all color and supervise press adjustments if necessary.

Pre-Press-Where Things Go Right-Or Wrong

There is an old saying that you should use the right tool for the right job, and with creating pre-press files for your project, this is very true.

When you are producing high-quality, offset lithography materials, there is no substitution for high-quality graphic design tools such as the Adobe Creative Suite (Illustrator, InDesign, PhotoShop) and Quark XPress. There are some other applications that can be used, but these are the most widely used because they are designed to work within the exacting color standards and protocols demanded by four-color printing.

If you talk to printers, you will find that few, if any, are willing to work with client-provided files such as Microsoft Word, Publisher, and other programs that are aimed at creating basic documents. More often than not, these applications are just not compatible with the software and output devices used by printers.

Programs such as Adobe InDesign and Quark XPress, are designed to be compatible with the software and standards used by lithographers and will provide for greater flexibility and accuracy for everyone throughout the pre-press and printing process.

Check with the printing company you will be working with before you start designing your project to see what programs and file types they prefer to work with.

Achieving Color Quality

Avoid doing pre-press work yourself unless you have the pre-press expertise or an experienced resource to do the work for you. A pre-press professional will have calibrated monitors so there is less of a chance of color problems, and they will have a workflow process so they can make sure all pre-press elements work together. Digital files delivered to a printing company need to work together flawlessly so there are no surprises after the job is printed. Also, four-color process printing is very exacting-what may look fine on a desktop printer may be blurry and lifeless when printed by offset lithography.

You should work through a graphic designer who has a lot of printing experience or work with a printer who will include in his price some time to go through your files and correct any pre-press problems before the job goes to press.

If you get several printing quotations, do not assume that the lowest bidder will necessarily deliver as good a print job as the high bidder or that because someone who is more expensive will deliver a better quality job. Be sure to look at samples of a printer’s work, especially projects that are similar in size and complexity as your project. Make sure your printing quotes are really an apple to apple comparison.

Working With PrintArt

If you do not like creating printing specifications and working with printers, consider using a graphic designer as your go-between. If you are working with someone to design your projects already, they may have several printers they like to work with and your designer can handle the technical issues and work with PrintArt on your behalf.

All printers are not created equal because printers vary in terms of press sizes and what is considered their ideal printing project. A printer with a smaller press might be more economical, but might have greater press limitations and could deliver a less than the first-rate job. This is why working with PrintArt makes sense, they have the equipment and expertise to handle your project.

Before your project is printed, be sure to look at digital or match print proofs to make sure you are happy with the quality of the proof. Many printers will allow you to critically examine the first color proofs and make color adjustments, providing you with a second set of color proofs prior to printing. Keep in mind that making color corrections will send your job back through pre-press and may delay the printing schedule significantly.

Press Proofing

Press proofing is one way to make sure you have no surprises after your project is printed. Usually, press proofing is done by the client, the project’s designer, or the printing sales representative handling the job. Keep in mind that some printers may charge extra to press proof as it means holding up the press run until the press proof is complete. Press hold-ups can be costly, especially if the press proof requires sending the job back to pre-press.

Press proofing is probably more important with long press-runs where you are printing tens of thousands of a brochure or other marketing materials. If you have a small print run of a few thousand, the time and effort required to press proof may not be worth it.

During a press proof, you should look for color fidelity by comparing the printed sheet against the matchpoint or digital proof. You also will want to look at solid areas making sure there are no dust spots creating white specks. Be sure to inspect a small type or type that is created using screens or reversed out of a color background.

Generally, minor color adjustments can be made to enhance or create final color balance in a four-color piece, however, extensive color adjustments on-press is not the way to correct poor quality pre-press work. When correcting on the press you are “tweaking”, and you will just not have the controls over individual images used within your print job as you do when the job is still in pre-press.

While slight color adjustments on-press is perfectly acceptable, keep in mind that any color adjustments will affect the length of the sheet; that is, anything ahead of or behind the area affected by color adjustments on press will be affected as it passes through the press.

Saving Money With Out of Town Printers

While it is tempting to use printing companies who advertise through the Internet and offer great pricing on four-color printing, keep in mind that many of these printers “gang” print, that is, they put your printing job on a large press sheet along with many other customers, so it may not be possible for your job to get the individual attention it needs. Press proofing may be difficult or impossible due to the location of the printer or the printing schedule (as some printers have three shifts).

Is Four Color Printing Worth The Price? The answer is yes for some companies and some situations, and no for others.

The bottom line is to consider carefully the reasons to use the four-color process in the first place and to take care when completing all pre-press work. Knowing your printer or your printer’s capabilities ahead of time will make for less stress and you will know what to expect if something does go wrong.

It can be a fairly complex process but don’t feel overwhelmed, reach out to PrintArt today, and explain your needs. Their customer service department will put together a cost-effective quote and help your vision come to reality!

PrintArt – Accurate Die Cutting

413 Interchange St.

McKinney, TX 75071

972.562.7921

https://www.printart-adc.com