UV printing is the most-efficient way to produce printed material in the commercial field and is starting to become the new standard. It has a variety of advantages, including flexibility, durability, high print qualities, and fast curing speeds. UV printed is appreciated for its ability to print on uncoated stocks and unusual substrates.

Besides the actual printer, UV inks also come with a variety of advantages compared to standard solvent-based inks. They are more environmentally friendly for one. They also provide a nice gloss, sharp contrast, resistance to smearing, light-fastness, and good opacity. Because the UV inks do not rely on evaporative agents, the ink does not stick or thicken during the press run.

Here are four of the major advantages of UV printers:

Flexibility

A UV printing machine is designed to print on virtually any non-absorbent or absorbent surface. This flexibility in printing makes it possible to easily print on more surfaces than every before. Printing on non-porous surfaces like hardboard and Styrene is now more common. A small print shop is given the option of printing on hundreds of different formats such as large banners, cards, clings, book covers, and similar retail items.

High Quality

UV printing means it is possible to avoid repeated runs through a traditional press machine due to low-quality prints. Since the UV inks are designed to sit on the surface of the printed material, it does not absorb the liquid. Therefore print work stays nice and crisp with vibrant and high-gloss colors.

Durability

A large banner with an image added using a UV printer is much more resilient to sun exposure, wear and tear, and scratches compared to the more traditional printing techniques. This is certain to benefit the companies displaying the large promotional signs since it is much less likely to appear weather-worn after one or two weeks in the sun.

Curing Speeds

A UV printer using instant drying ink means it is possible to work faster and more efficiently. Since the ink is dry the instant it leaves the printer there is no more issues related to ghosting of images or waiting to do proofs. The faster work process means it is possible to move to the finishing and binding work sooner.

All in all, for the customer searching for increased flexibility, durability, and speed for the wide-ranging commercial needs, the UV printer is certain to offer one of the most desirable pieces of equipment in the industry.

Get a lot more information on the most-effective commercial printing equipment including the UV printer and Flatbed printer.

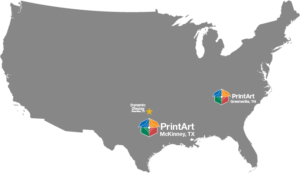

It can be a fairly complex process but don’t feel overwhelmed, reach out to PrintArt today, and explain your needs. Their customer service department will put together a cost-effective quote and help your vision come to reality!

PrintArt – Accurate Die Cutting 413 Interchange St. McKinney, TX 75071 972.562.7921 https://www.printart-adc.com

PrintArt – Accurate Die Cutting 413 Interchange St. McKinney, TX 75071 972.562.7921 https://www.printart-adc.com